Enhancing Efficiency and Sustainability with Homogenizer Technology in Sludge Reductiontroduction Homogenizer technology is crucial for improving fuel management and reducing sludge in maritime operations. This advanced approach significantly enhances the efficiency of fuel separators, resulting in lower sludge production and improved fuel efficiency. Benefits of Homogenizer Technology Improved Separator Efficiency:

Enhanced Fuel Efficiency:

Environmental Impact:

Operational Smoothness:

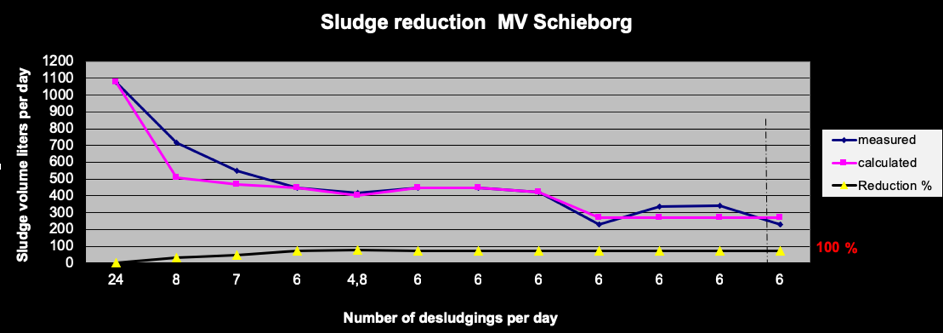

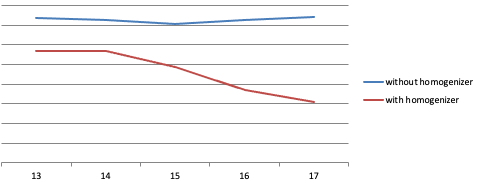

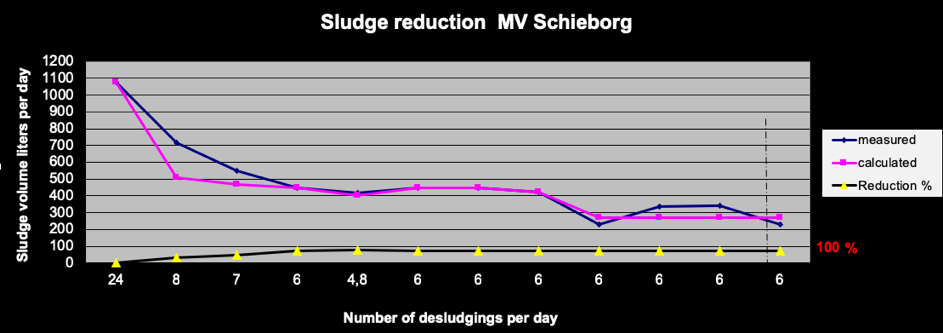

Case Studies and Real-world Applications Practical Implementations: Vessels using homogenizer technology have reported significant improvements in separator performance and sludge reduction. This technology effectively handles heavy fuel oils, maintaining engine safety and reliability even with lower quality fuels.

Conclusion

Homogenizer technology is essential for modern maritime operations, offering significant benefits in operational efficiency, fuel economy, and environmental sustainability. By enhancing the fuel pre-treatment process, homogenizers reduce sludge production, improve fuel efficiency, and boost overall engine performance. At IPCO Power, we recognize that not all fuel-saving initiatives on vessels impact the Specific Fuel Oil Consumption (SFOC). While SFOC is essential and measured through the fuel consumed by the engine in relation to the power produced, it doesn’t capture all efficiencies. Enhancing the usage of fuel from your bunker tank may not reflect in the SFOC but leads to significant fuel savings and reduces sludge disposal needs.

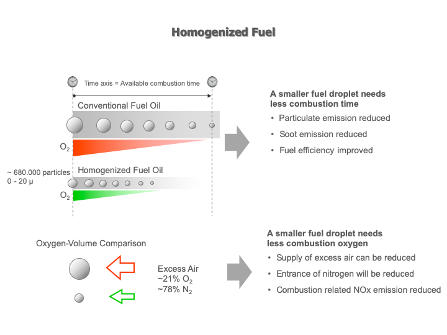

📏 In adherence to the stringent German Rule—derived from the German Wasserpolizei and widely accepted internationally—Hamburg port control mandates a minimum sludge production of 1.5% of fuel consumption. This ensures that sludge isn’t dumped into the sea and meets both local and global environmental standards. Although reducing sludge production might not improve SFOC directly, it significantly betters the overall fuel efficiency of vessels. IPCO Power’s FID Reducer is a game-changer in this field. Positioned before the centrifuge in your fuel processing system, our FID Reducer is designed to decrease the size of fuel droplets, enhancing the efficiency of centrifuges and filters. This not only cuts down sludge production but also extends the life and maintenance intervals of your equipment, boosting operational efficiency. 🔬 The efficiency gains also depend on the size of asphaltenes in the fuel, with larger asphaltenes translating to more significant fuel conversion—up to 10% of asphaltenes can be transformed into usable fuel, achieving savings of between 0.3% and 1.00%. Certified under the International Oil Pollution Prevention (IOPP) Marpol Leg. 73/78 Annex 1, our FID Reducer ensures compliance with international standards, allowing for smoother port controls and reduced inspection issues. 🌍 With every step towards reducing sludge, we not only lower disposal costs but also enhance the environmental footprint of maritime operations. Join us at IPCO Power as we set new standards in maritime efficiency and environmental stewardship. #MaritimeIndustry #IPCO Power #Sustainability #FuelEfficiency #EnvironmentalImpact Homogenizers enhance the fuel's properties, impacting its viscosity index 🔄. A fuel homogenizer will change the surface tension of the fuel. The primary function of a homogenizer is to break down the larger fuel particles into smaller, more uniform sizes, and this process also affects the fuel's surface properties.

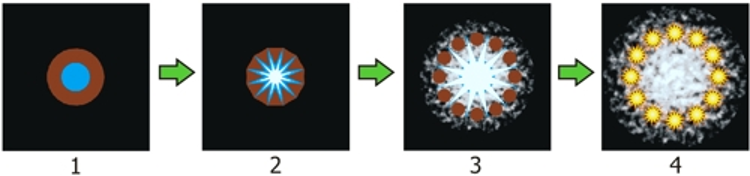

When the fuel is passed through a homogenizer, the high-pressure and shear forces disrupt the larger fuel aggregates, leading to a more homogeneous fuel mixture. This mechanical process reduces the surface tension of the fuel. Lower surface tension improves the fuel's ability to form finer droplets during the atomization process in the engine's fuel injectors, leading to more efficient combustion. By altering the surface tension, the homogenizer helps create a fuel that is more easily vaporized and mixed with air, enhancing the combustion process, improving fuel efficiency, and potentially reducing emissions. For engines with a viscosity range of 14 to 16 cSt, operating at the higher end (16 cSt) when using a homogenizer brings significant benefits: Lower SFOC: Improved fuel atomization boosts combustion efficiency, reducing fuel consumption 💧🔥. Integrating a homogenizer can thus lead to substantial operational savings and environmental benefits. Opt for the higher end of your fuel's viscosity range to see the best results. Learn more at: https://lnkd.in/ewErxvNh Embrace efficiency and sustainability today! 🌱 #FuelEfficiency 💡 #SustainableTechnology ♻️ #MarineEngineering ⚓ #IndustrialEngineering 🏭 At IPCO Power, we've dedicated years to mastering water-fuel emulsion technology. Our journey started with a clear objective: to improve fuel efficiency while reducing emissions in maritime operations. 🌱🚢

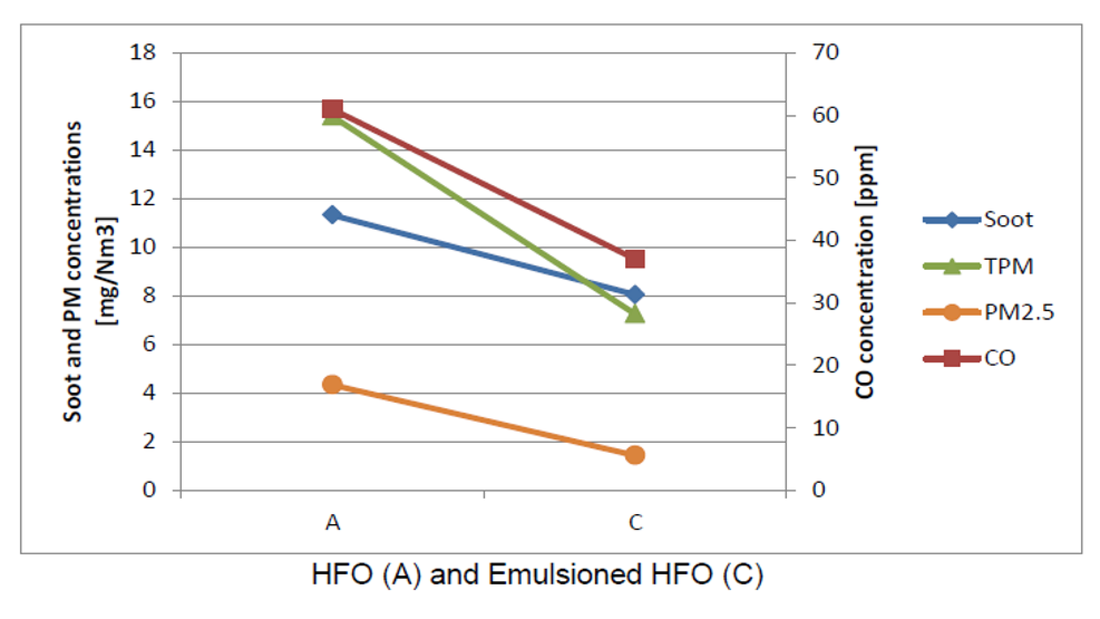

Understanding the critical importance of emulsion quality, we've identified the optimal point of water injection - directly at the fuel feed towards the mix tank. This process, devoid of unnecessary circulation, ensures a perfect blend. 🎯💧 Following this, our unique fuel homogenizer takes over, creating a stable, efficient emulsion. This step is crucial: without it, vessels risk the presence of free water in their engines, leading to inefficiencies and potential safety hazards. 🛠️⚙️ Over the years, we've seen various methods and technologies emerge. However, the effectiveness of water-fuel emulsion depends on precise execution and the right equipment. At IPCO Power, we've refined our approach based on comprehensive research and real-world applications. 📊🔍 With more than 140 systems operational worldwide, our technology is not just proven; it's a testament to our commitment to sustainability and efficiency in the maritime industry. 🌍🚀 Our FID Injector system, available since 2008, remains the most cost-effective solution for reducing NOx, CO2, PM, and soot emissions in maritime operations. It's not just about innovation; it's about providing a practical, efficient solution that stands the test of time. 💡💸 Join us in our journey toward cleaner, more efficient maritime operations. IPCO Power is here to guide you every step of the way. 🚢🌿 Learn more at: https://lnkd.in/eZZ9-NV #IPCO Power #MarineInnovation #Sustainability #Efficiency In the maritime sector, the battle against contaminated fuel and its detrimental effects on ship operations is ongoing. Contaminated fuel can lead to clogged separators and filters, causing significant operational disruptions and maintenance challenges. However, with the right approach, these issues can be effectively mitigated. ⚙️💧

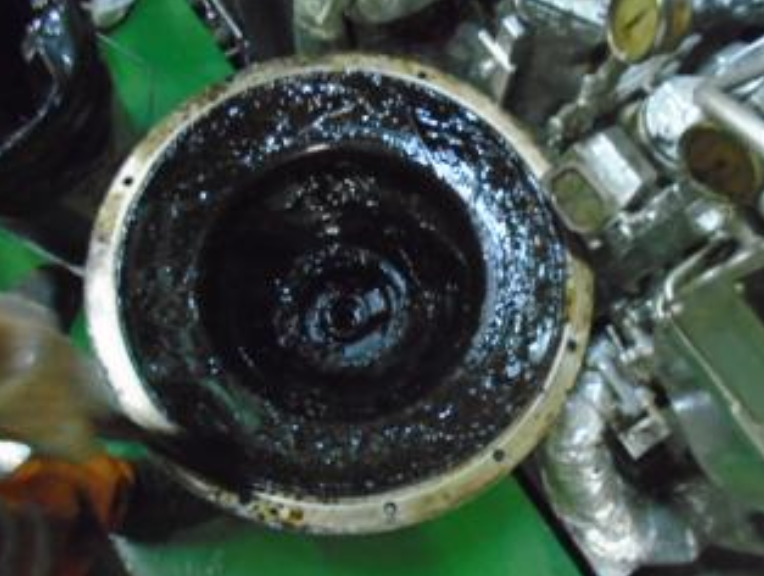

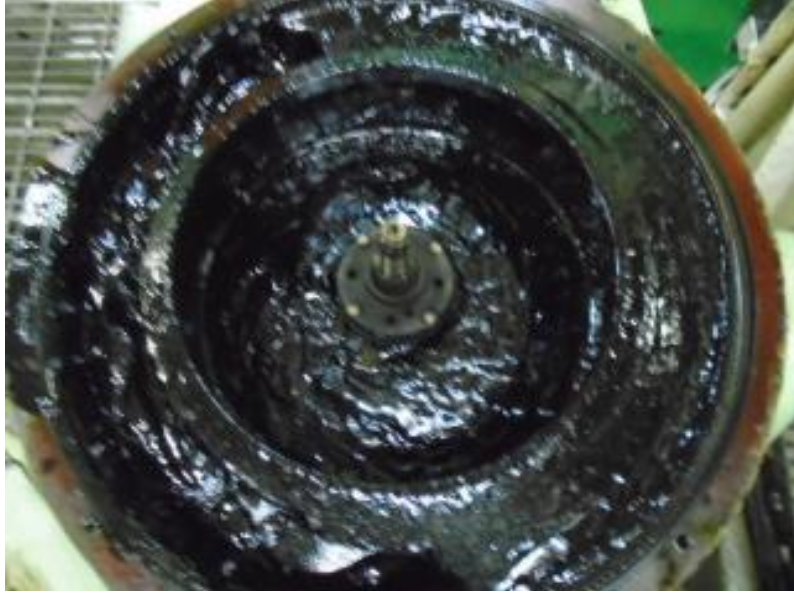

Our advanced fuel treatment solutions, including state-of-the-art homogenization technology, are designed to tackle the very heart of this problem. By ensuring a more uniform fuel mixture, these solutions significantly reduce the risk of clogging, enhancing operational efficiency and reliability. 🌊✨ Key factors such as commingling incompatible fuels, extended storage, and improper storage temperatures can exacerbate fuel contamination issues. Our technology addresses these concerns by improving fuel quality. 🔧🔬 Investing in advanced fuel treatment is not just about preventing clogs; it's about securing uninterrupted operations, reducing maintenance costs, and ensuring compliance with environmental regulations. Let's embrace innovative solutions to keep our vessels running smoothly, even in the face of contaminated fuels. 💼🌿 Discover how our fuel treatment solutions can transform your operational efficiency. Protect your machinery, reduce downtime, and maintain high performance standards, regardless of fuel quality challenges. 🛠️⏳ Check out: https://lnkd.in/gXXsq76 Water in your vessel's oil isn't just a nuisance—it's a threat. According to Chevron's guidelines, even small amounts can escalate to serious issues. With precise monitoring from the ZelenTech ZT-100, you'll have a clear warning before reaching critical levels.

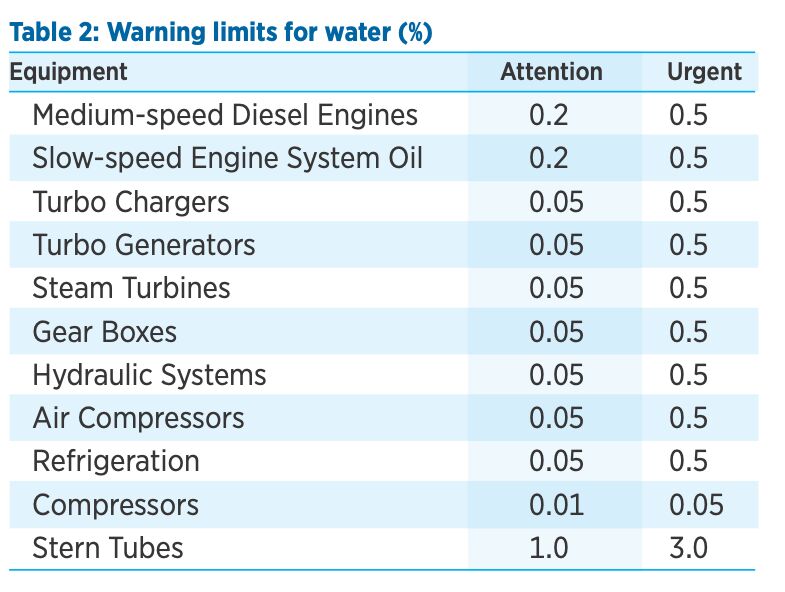

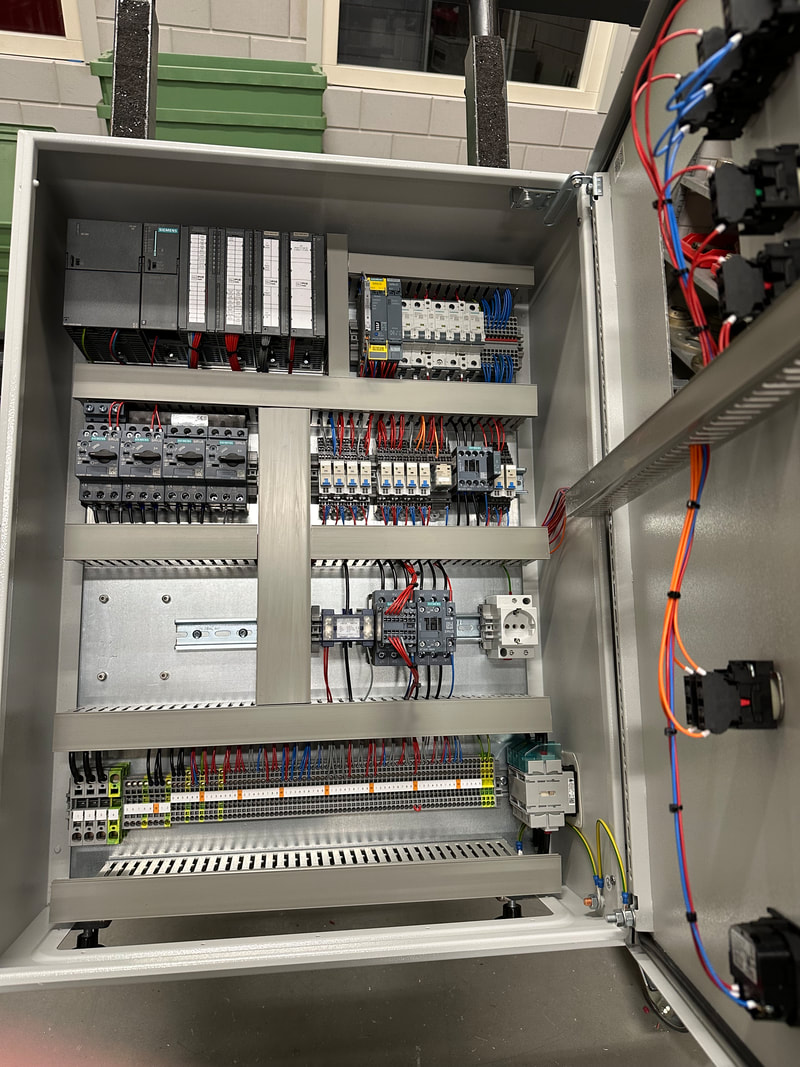

📊 See the table for clear limits. With ZelenTech, you're always within safe levels. Why worry? Water triggers sludge, clogs oil lines, degrades additives, and corrodes parts. It can break down the lubrication that your vessel's systems rely on. The result? Unplanned downtime, costly repairs, and reduced equipment life. The ZelenTech ZT-100 gives you the power to measure beyond saturation, so you can address issues before they start. Check out the included table to see the maximum water percentages your equipment should handle. Stay safe and efficient. With ZelenTech, you're always informed, always protected. For more details visit https://lnkd.in/g9zbMKa From drafting tables to deployment, we've managed every detail within our own facilities, ensuring unmatched excellence in marine engineering. Here's a first look at the electrical cabinets designed and built entirely in-house for the Water Fuel Emulsion system aboard the HAL Koningsdam. Our commitment to innovation and sustainability is at the heart of this project, driving us forward in the maritime industry.

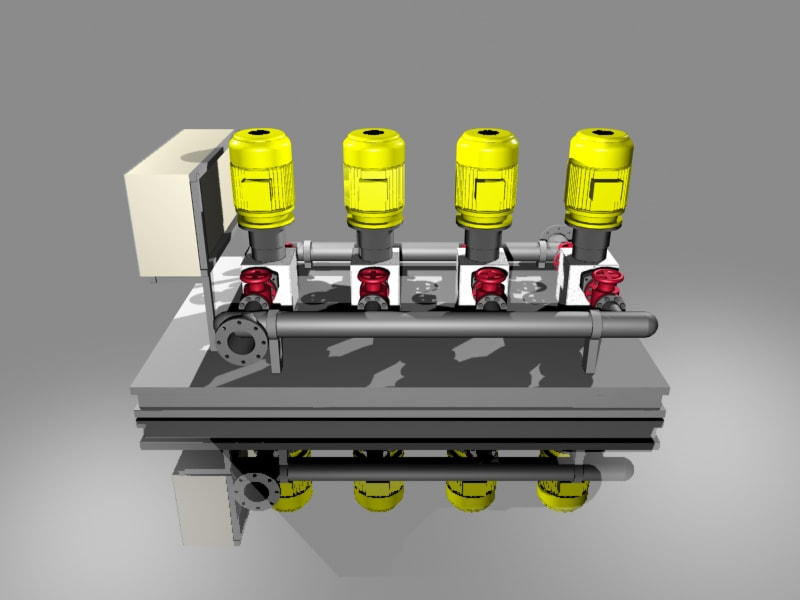

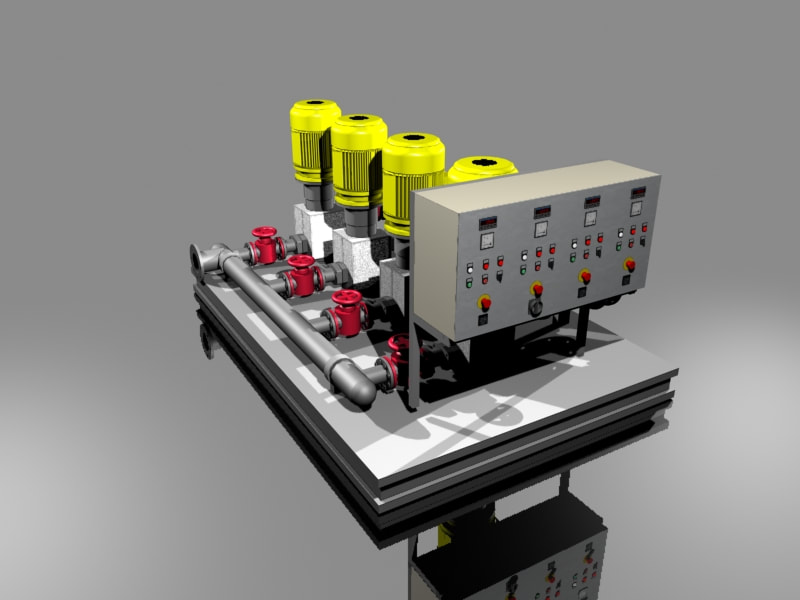

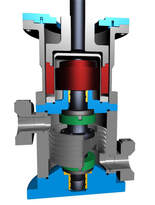

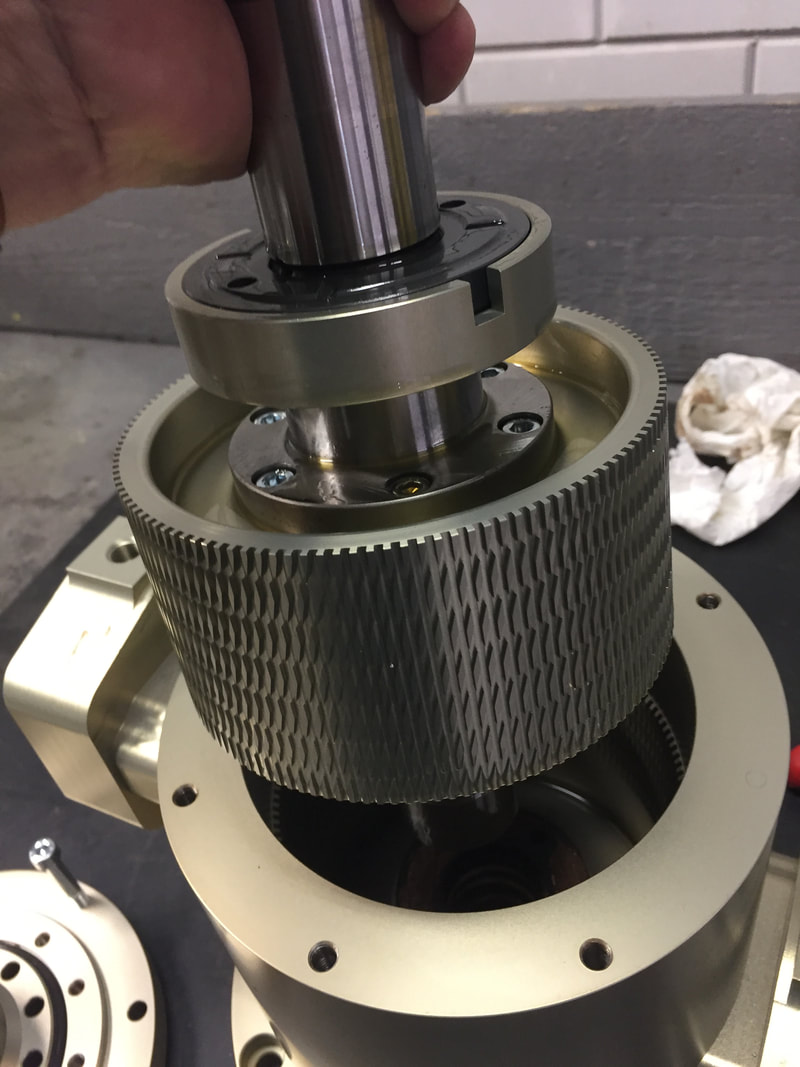

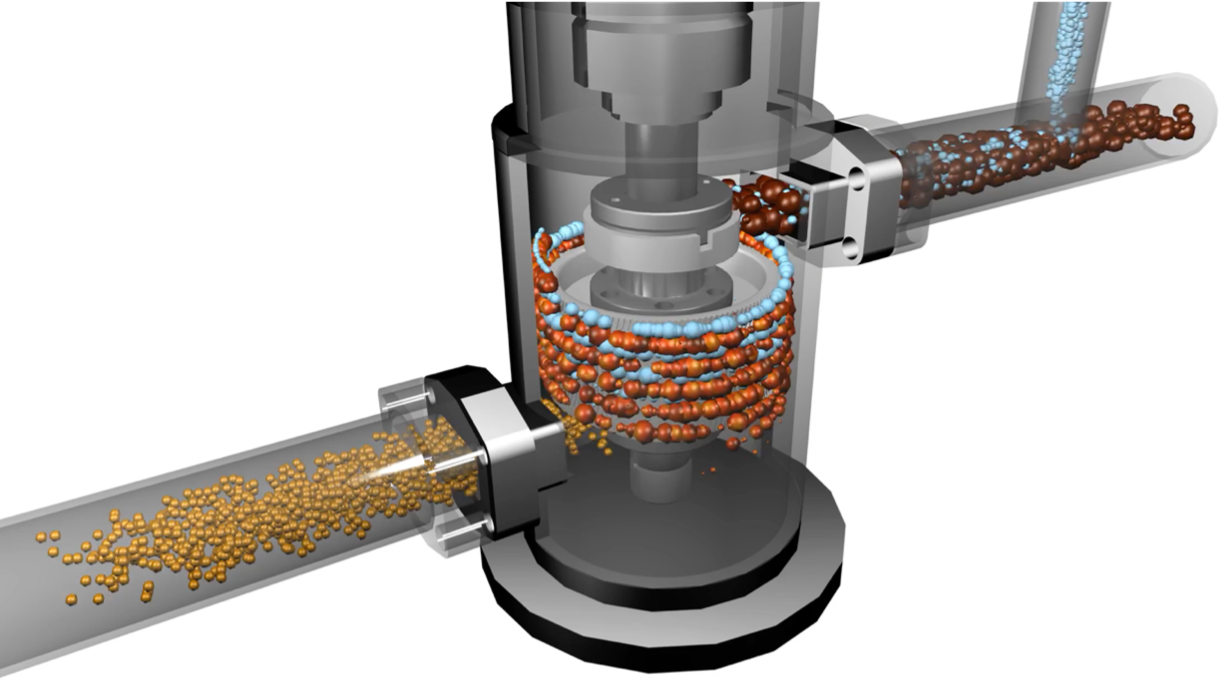

Look at https://lnkd.in/eZZ9-NV for more details about the product and at https://lnkd.in/efayfXD5 for more about our engineering possibilities. #Innovation #MarineEngineering #Sustainability #HALKoningsdam  At IPCO Power, we take pride in our established legacy of innovation and excellence in fuel treatment. Today, we're shining the spotlight back on one of our flagship offerings – the FID 300 system, known for its unparalleled capacity and reliability in handling a flow of 30,000 liters per hour. 🌐 But why stop there? For operations demanding even higher capacities, we offer tailored solutions that push the boundaries of efficiency and performance. Case in point: our bespoke 4 x C300 Fuel Homogenizer system, designed to seamlessly manage an impressive 120,000 l/h. 🔥 Highlights of the FID 300 & 4 x C300 Systems: Supreme capacity: Engineered for the most rigorous demands of fuel treatment. Customized engineering: Tailored to fit the specific needs of your operations, ensuring optimal performance. 👥 Whether you're revisiting your current needs or planning for future expansion, IPCO Power is here to support you with high-capacity systems that have stood the test of time. 🔗 Discover how the FID 300 or our custom 4 x C300 system can transform your operations. Visit our website www.ipcopower.com or contact us directly to explore more. Together, let's continue to drive excellence in every flow. #IPCOPower #FID300 #FuelHomogenizer #SustainableInnovation #shipping Introduction: Efficiency isn't just a preference in maritime operations; it's a prerequisite. With fuel costs comprising a significant portion of operational expenses, ship owners and operators are constantly seeking innovative solutions to maximize fuel utilization. Enter the Homogenizer—an advanced milling machine engineered to revolutionize fuel quality aboard ships. This article delves into the transformative influence of homogenizers in enhancing combustion efficiency, reducing maintenance, and mitigating environmental impacts in maritime operations. Understanding Homogenization: At its essence, a homogenizer is a mixer engineered to achieve a uniform and consistent mixture by subjecting materials to various forces within a confined space. In maritime operations, homogenizers are instrumental in enhancing fuel quality, especially concerning heavy fuel oil (HFO) utilized in main engines. The Science Behind Fuel Homogenization: Fuel oil typically comprises water, paraffin, solid impurities, sulfurous organic compounds, and hydrocarbons. The heterogeneous nature of fuel oil presents challenges during combustion, resulting in inefficient burning and the generation of toxic byproducts. Homogenization addresses these issues by breaking down sulfur and paraffins, enhancing dispersion, and ensuring uniformity in the fuel mixture. Harnessing Cavitation for Efficiency: Cavitation technology stands out as one of the most efficient methods of fuel homogenization. Cavitation, a phenomenon akin to boiling yet distinct in its mechanisms, involves the formation and collapse of microscopic bubbles in a liquid. When applied to fuel homogenization, cavitation disrupts molecular bonds, facilitates dispersion, and enhances combustion efficiency. Benefits of Homogenized Fuel: The advantages of utilizing homogenized fuel are manifold. Enhanced combustion efficiency translates to reduced equipment wear, decreased maintenance costs, and improved environmental sustainability. By optimizing fuel quality, homogenizers empower ship operators to maximize the burnable fuel fraction, thereby enhancing operational efficiency and profitability. The Homogenizer Solution for Maritime Operations: Tailored to address challenges associated with heavy fuel oil, the Homogenizer provides a chemical-free approach to fuel optimization. Equipped with a hermetically sealed magnetic coupling drive and specialized materials capable of withstanding high pressure and temperature, the Homogenizer ensures reliable performance in diverse maritime settings. Fueling the Future: Homogenizers and Biofuel Integration As the maritime industry shifts towards sustainable solutions, homogenizers' role in fuel optimization extends beyond conventional fuels. With the emergence of biofuels as a viable alternative, homogenizers are poised to play a pivotal role in enhancing efficiency and reducing environmental impact. Biofuel Challenges Addressed: Biofuels pose unique challenges due to their composition and properties, including unmixing, oxidative degradation, and microbial contamination. Homogenizers offer effective solutions to these challenges, ensuring the stability, efficiency, and reliability of biofuels throughout maritime operations. Unlocking the Potential of Biofuels:

By integrating homogenization technology into biofuel processing and storage, ship owners and operators can fully exploit the potential of biofuels as a sustainable energy source. Homogenizers mitigate issues such as unmixing, oxidative degradation, and microbial contamination, maximizing the benefits of biofuels while minimizing drawbacks. A Sustainable Future at Sea: Amidst the maritime industry's transition towards cleaner fuels, homogenizers emerge as pioneers of innovation. By optimizing the quality and performance of both traditional fuels and biofuels, homogenizers contribute to a more sustainable future at sea, where efficiency, reliability, and environmental responsibility converge. Conclusion: In a maritime landscape driven by efficiency and sustainability, homogenizers stand out as indispensable tools for fuel optimization. By leveraging cavitation and ensuring uniformity in fuel mixtures, homogenizers facilitate enhanced combustion efficiency, reduced maintenance, and long-term cost savings. As the maritime industry evolves, the significance of homogenizers in shaping a more efficient and environmentally conscious future remains unparalleled. Check out our products It's a momentous occasion for IPCO Power as we commemorate 14 years since the groundbreaking installation of our water fuel emulsion system onboard HAL Rotterdam, a partnership that set the stage for transformative change in the maritime industry!

From those early beginnings, our collaboration with Holland America Linepaved the way for pioneering advancements in fuel efficiency and emissions reduction. Today, we proudly extend our reach with our latest order for HAL Koningsdam. With over 140 water fuel emulsion systems supplied to date, IPCO Power continues to lead the charge in sustainable shipping solutions. By implementing our emulsified fuel technology, we're not only enhancing combustion efficiency but also significantly reducing fuel consumption and emissions of NOx, HC, and PM pollutants. As we reflect on this milestone, we extend our heartfelt gratitude to our partners, clients, and dedicated team members who have been instrumental in driving forward our mission of sustainable maritime practices. Here's to 14 years of progress, innovation, and environmental stewardship, and to many more years of pioneering solutions that propel us towards a greener future for generations to come! #IPCO #SustainableShipping#FuelEfficiency #EmissionsReduction #MaritimeInnovation #GreenFuture n an era where sustainability and environmental responsibility are paramount, the world is turning its attention to biofuels as a cleaner, greener alternative to traditional fossil fuels. However, as we venture further into the realm of biofuels, we are encountering new challenges. IPCO Power, a pioneer in fuel technology, is stepping up to address these challenges head-on with cutting-edge solutions.

Fuel Homogenizer: A Key Player in Biofuel Evolution Biofuels have the potential to reduce greenhouse gas emissions and lessen our dependence on fossil fuels, but they are not without their complexities. Variability in feedstock quality and composition can lead to performance issues and increased maintenance costs for engines and equipment. That's where IPCO Power's Fuel Homogenizer comes into play. Our Fuel Homogenizer is a game-changer for the biofuel industry. It ensures that biofuels are blended to perfection, achieving consistent quality and performance. By eliminating the inherent inconsistencies of biofuel feedstocks, we are enabling the industry to confidently transition to cleaner, renewable energy sources. FID Blender: On-Board Blending Made Easy As we adapt to a world with a growing reliance on biofuels, efficient blending is vital. IPCO Power's FID Blender simplifies the process of blending different biofuel components on board, providing a seamless solution for achieving the optimal biofuel mix for any application. This not only enhances engine performance but also streamlines operations, reducing costs and environmental impact. FID Recycler: Tackling Biofuel-Related Challenges Head-On One of the challenges associated with biofuels is the potential for bacterial growth within fuel tanks, which can lead to corrosion, clogging, and other costly issues. IPCO Power's FID Recycler offers a proactive solution by preventing bacteria growth and maintaining the integrity of biofuels. With our on-board tank treatment system, biofuels remain in pristine condition, ensuring a smooth and trouble-free journey. At IPCO Power, we are not just witnessing the evolution of biofuels; we are actively shaping it. Our commitment to sustainable energy solutions goes hand in hand with our dedication to innovation. By providing reliable and efficient tools like the Fuel Homogenizer, FID Blender, and FID Recycler, we empower the biofuel industry to thrive in an environmentally conscious world. As the world continues its transition towards renewable energy sources, IPCO Power stands at the forefront, ready to support the biofuel industry's growth and development. Together, we can create a cleaner, more sustainable future. Connect with us to learn more about our cutting-edge solutions and join us in revolutionizing the biofuel industry. Some manufacturers of separators have voiced concerns regarding the influence of homogenizers on the performance of separators. Their worry is that homogenizers could affect the separator’s ability to efficiently separate substances denser than water and impede the process of water extraction. Fundamentally, the purpose of centrifuges and filters is to extract water and inorganic impurities from fuel, with the assumption that organic components of the fuel will be combusted in the engine instead of being discharged into the slop tank. Homogenizers aim to minimize fuel waste to less than one percent by reducing the size and mass of fuel droplets, thereby enhancing the ability of centrifuges and filters to remove inorganic pollutants from new fuel. Refineries have advanced in reducing contaminants like cat-fines in Heavy Fuel Oil (HFO), and protecting engines is a top priority. IPCO Power's homogenizers are crucial in this process by diminishing fuel droplet size and mass, which in turn boosts the performance of centrifuges and filters. In the IPCO Power homogenizer, fuel is forced through a 300-micron gap between the stator and rotor of the homogenizer, which spins at 3000 RPM, creating fluid shearing. The sludge expelled by the fuel separator is typically composed of three main elements:

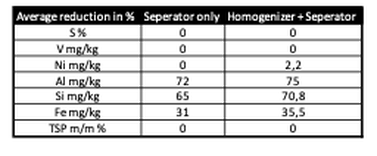

The ratio of these elements can vary based on the fuel’s state, quality, and the specifications and settings of the fuel separator. FRAS Technology has verified that homogenizers do not affect the volume and size of the hard (inorganic) particles in the fuel. A report by CIMAC, comparing particle size distribution and count with and without a homogenizer prior to centrifugation, indicated a 4-6% improvement in particle removal efficiency with the use of a homogenizer/separator system compared to using a separator alone. IPCO Power has conducted thorough research on the efficiency of separators through onboard installations, analyzing bunker samples before and after treatment by the separator, both with and without the homogenizer active. These studies showed that the presence of the homogenizer notably enhanced the separator’s removal effectiveness and achieved a reduction in sludge by 50 to 80%. Any decline in separator efficiency would be quickly noticeable. IPCO Power is pleased to report that since 2006, all installed homogenizers have consistently met and surpassed customer expectations, delivering the high level of performance our customers require. IPCO Power welcomes any inquiries and is ready to provide further details as needed.

As the world becomes increasingly concerned about the devastating impact of carbon dioxide emissions on our planet, the demand for sustainable alternatives has never been greater. Biofuels have emerged as a promising solution, offering a renewable and eco-friendly alternative to traditional fossil fuels.

|

Categories

All

Archives

March 2024

AuthorBart Sluimer is the General Manager of IPCO Power. IPCO Power is an international company specialized in environmental solutions for the petrochemical-, shipping- and power industry. Find us on google+ and twitter |

||||||||||||||||||||||||||||||||||||||||||