Optimize Your Fuel System with IPCO Power's Integrated Solutions

Unlock unparalleled efficiency and environmental benefits with IPCO Power's synergistic approach to fuel treatment. Our tailored combination of the FID Reducer, FID Improver, and the optional FID Injector represents the pinnacle of innovation in emissions control and fuel quality enhancement.

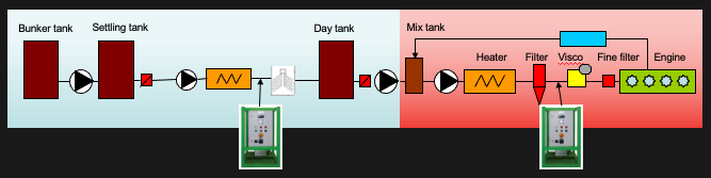

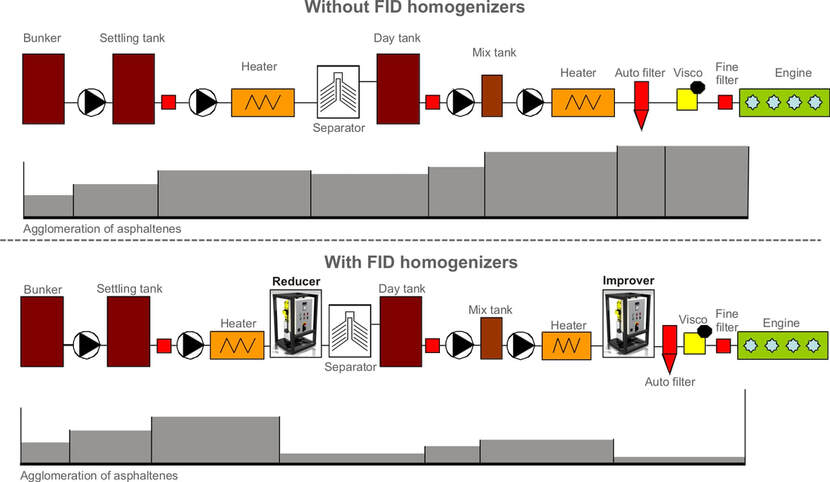

Stage One: Precision Fuel Preparation with the FID Reducer

Strategically installed before the separator, the FID Reducer meticulously refines fuel droplets, facilitating enhanced separation and retention of valuable fuel components. This crucial step prevents the loss of fine fuel particles, setting the stage for optimal combustion efficiency.

Stage Two: Combustion Optimization with the FID Improver or FID Injector

As fuel advances towards the engine, it risks re-agglomeration, potentially compromising combustion quality. The FID Improver, or for those seeking even greater efficiency, the FID Injector, is employed to counteract this. By further refining fuel droplets to an ideal size of approximately 3 microns, these systems ensure superior atomization and fuel-oxygen integration, significantly boosting combustion efficiency and fuel economy.

The Impact: Enhanced Performance and Environmental Stewardship

Implementing our recommended solutions not only uplifts fuel quality but also dramatically diminishes soot and particulate matter emissions. The outcome is a dual triumph of significant fuel savings and a robust reduction in CO2 emissions, contributing to a more sustainable operation and aligning with global efforts to mitigate climate change.

Strategically installed before the separator, the FID Reducer meticulously refines fuel droplets, facilitating enhanced separation and retention of valuable fuel components. This crucial step prevents the loss of fine fuel particles, setting the stage for optimal combustion efficiency.

Stage Two: Combustion Optimization with the FID Improver or FID Injector

As fuel advances towards the engine, it risks re-agglomeration, potentially compromising combustion quality. The FID Improver, or for those seeking even greater efficiency, the FID Injector, is employed to counteract this. By further refining fuel droplets to an ideal size of approximately 3 microns, these systems ensure superior atomization and fuel-oxygen integration, significantly boosting combustion efficiency and fuel economy.

The Impact: Enhanced Performance and Environmental Stewardship

Implementing our recommended solutions not only uplifts fuel quality but also dramatically diminishes soot and particulate matter emissions. The outcome is a dual triumph of significant fuel savings and a robust reduction in CO2 emissions, contributing to a more sustainable operation and aligning with global efforts to mitigate climate change.

Key Benefits of Our Combined Solution:

Embrace a Future of Efficiency and Sustainability

By integrating IPCO Power's FID Reducer and FID Improver—or enhancing your system further with the FID Injector—you're not just optimizing your fuel system; you're investing in a greener, more efficient future. Discover the IPCO difference and lead the way in sustainable fuel management.

- Fuel Efficiency: Achieve up to 1.5% savings for 4-stroke engines and up to 2.5% for 2-stroke engines, fostering economic and environmental efficiency.

- Maintenance Reduction: Experience decreased demand for separator and engine maintenance, streamlining operations and extending equipment lifespan.

- Environmental Advantages:

- Sludge Reduction: Cut sludge production by up to 80%, easing the burden on waste management systems.

- NOx Emissions: Attain up to a 20% reduction with the Injector, surpassing traditional emissions standards.

- Particulate Matter: Achieve up to a 90% reduction with the Injector, significantly clearing smoke emissions and enhancing air quality.

- CO2 Reduction: Directly decrease your carbon footprint through optimized fuel consumption.

Embrace a Future of Efficiency and Sustainability

By integrating IPCO Power's FID Reducer and FID Improver—or enhancing your system further with the FID Injector—you're not just optimizing your fuel system; you're investing in a greener, more efficient future. Discover the IPCO difference and lead the way in sustainable fuel management.