VOCs are everywhere: at homes, at dry cleaning units, at food processors, at petroleum refineries, at airports and automobile service stations, at electronics and chemical plants, at print and paint shops etc. VOCs are those chemicals that exposed to air volatilize readily. So, these compounds contribute to air pollution by their vapour and to water and soil pollution by that fraction which can be carried deep into the soil by rainwater and melting snow. VOC and the environment: VOCs are dangerous for humans, fauna and flora. Firstly, these compounds have been proved to cause a variety of adverse health effects (Minnesota Department of Health, 2003, Regional Environmental Assessments, 2002; U.S. EPA, 2003). Generally, allergic skin reaction, dizziness, headaches, eye and respiratory tract irritation, coughing, visual disorders, memory impairment, confusion, anemia and fatigue are some of the symptoms associated with short-term exposure. Kidney, liver, brain damage, cardiac sensitization reactions and also damage to the nervous, reproductive and immune systems are caused by long-term exposure. VOCs are also “endocrine impostors”. Some are also known or suspected of causing cancer. Also, the natural plant processes can be destroyed or interrupted by some organic volatile compounds. In the atmosphere these chemicals are transformed in other compounds even more dangerous for humans, fauna and flora. The ground level or “bad” ozone, a key ingredient of urban smog, is created by a chemical reaction between oxides of nitrogen (NOx) and volatile organic compounds in the presence of sunlight. Repeated exposure to ozone pollution may cause a variety of health problems (Clean Air Counts, 2003); ozone also reduces the growth rate of trees and agricultural production. VOCs participate in the greenhouse effect, acid rains and stratospheric or “good” ozone depletion, which are serious environmental problems (Avila et al., 1998). Consequently, VOCs are a great group of air pollutants and our duty is to eliminate them from being released. For this reason, firstly, we must know who are they and which are their sources.

Heavy Fuel Oil (HFO) is not homogenous and has an average droplet size of 70 micron and larger.

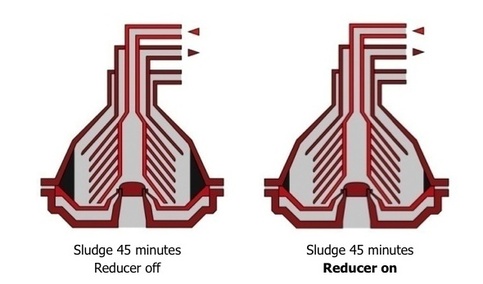

It contains numerous much larger clusters of asphaltenes and complex long-chain hydro-carbons. It is a refinery waste stream product with a high BTU content used as fuel oil. Centrifuges and automated filters are used to clean the fuel. A percentage of the purchased fuel ends up in the slop tank. HFO needs to be heated and pressurized before it can be used to operated engines or boilers. Exposing fuel to heat and pressure will unavoidably increase the size and mass of the fuel droplet, change the physical condition of the oil and negatively impact the combustion process. Implementing IPCO Power Fluid Shearing Technology reduces fuel droplet size to 3 micron and smaller to enhance the cleaning process and reduce the waste stream going to the slop tank for disposal. IPCO Powers FID Reducer Sludge Reduction Systems are installed directly before the centrifuge. As a result of the reduction in fuel droplet size, centrifuges and filters will be able to more effectively remove in-organic contaminants and stay clean much longer. Consequently, sludge generation from centrifuges and filters will be reduced by approx. 50 to 80% as shown in the below diagram*. As a result, centrifuge and automated filter flushing intervals will have to be adjusted and will be significantly extended. * based on vessel evaluation reports  It is currently common practice that chemical tank barges having contained volatile cargos, degas their tanks into the atmosphere while sailing to the next loading point. In the context of sustainable development, there is growing pressure to limit degassing into the atmosphere. With the Refrigerated Vapour Recovery System (RVRS) IPCO Power can offer a solution to reduce the VOC emissions from degassing events. The system recovers clean product from the vapours without reportable emissions. PURGIT RVRS uses a proprietary system that condenses and recovers tank vapours. Depending on the application PURGIT's condensers are capable to recover over 99% of the VOC. The working of the PURGIT Refrigerated Vapour Recovery System PURGIT RVRS uses a proprietary system that condenses and recovers tank vapours. This system draws the vapours out of the tank with a blower and then pushes them through a series of condensers. The VOC vapours are condensed back to their liquid phase and transferred to a holding tank or inserted right back into the cargo fill line. Depending on the application PURGIT's condensers are capable of recovering over 99% of the VOC. With few moving parts and stainless steel construction, these units are designed to operate for many years with minimal service. With the RVRS system VOC compounds are easily recovered. There is no combustion. Using non-polluting nitrogen as the refrigerant, this system is capable of the very low temperatures necessary to condense a wide range of products*. The RVRS's vapour recovery unit have been thoroughly tested in the field with a wide variety of products and have established a long track record of reliability and success. *) Including chlorinated products Closed Loop Tank Degassing The PURGIT RVRS system is designed to degas atmospheric or inert barges (low or zero O2) and keep it inert throughout the operation. Drawing VOC vapours out of the tank, the PURGIT system condenses and removes the hydrocarbons from the vapour stream, returning only the non-condensable to the tank. Condensing and removal of the VOC in the tank or barge will continue until the required LEL level is reached. Normally it takes 1,5 times the volume of the tank. The RVRS will require approximately 1000 L nitrogen per 1000 cub of vapour. |

Categories

All

Archives

March 2024

AuthorBart Sluimer is the General Manager of IPCO Power. IPCO Power is an international company specialized in environmental solutions for the petrochemical-, shipping- and power industry. Find us on google+ and twitter |