IPCO Power Vapour Processing System

The Vapour Processing System (VPS) is designed to avoid VOC emissions. At the same time the VPS contributes to the sustainable development of bulk-handling companies by reducing their electricity consumption.

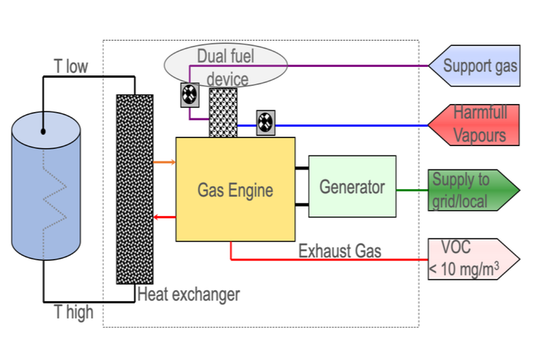

The VPS consists of a modified gas engine with a continuous dual fuel device and is controlled by a specially designed engine, generator and fuel management system. The VPS operates as a fully automatic device. As soon as any hazardous vapour is detected the system starts operating.

The VPS consists of a modified gas engine with a continuous dual fuel device and is controlled by a specially designed engine, generator and fuel management system. The VPS operates as a fully automatic device. As soon as any hazardous vapour is detected the system starts operating.

99% VOC reduction

The fuel management system will constantly monitor and adjust all settings within the system to ensure an efficient and effective operation. When the system does not detect any vapour it will shut down automatically. The collected vapour is converted into electricity by the gas engine and generator. The recovery of the engine heat can be used for heating storage tanks or/and buildings at the terminal. The VOC emissions are reduced up to 99,9% with an energy recovery efficiency of 31% for electricity production up to 76% (when heat recovery is included).

Generating of electricity with VOC emissions

The prime advantage of the VPS is the generating of electricity during the process instead of consuming it. The produced electricity can be utilized by the terminal to reduce purchase from the grid. If there is any surplus production of electricity from the VPS, it can be sold to the grid.

In this way real savings can be established that will positively contribute to the sustainable and society responsible enterprising of your company.

In this way real savings can be established that will positively contribute to the sustainable and society responsible enterprising of your company.

How does our Vapour Processing System work

The VPS consists of a modified gas engine with a continuous dual fuel device and is controlled by a specially designed engine, generator and fuel management system. The VPS operates as a fully automatic device. As soon as any hazardous vapour is detected the system starts operating.

The fuel management system will constantly monitor and adjust all settings within the system to ensure an efficient and effective operation. When the system does not detect any vapour it will shut down automatically. The collected vapour is converted into electricity by the gas engine and generator. The recovery of the engine heat can be used for heating storage tanks or/and buildings at the terminal. The VOC emissions are reduced up to 99,9% with an energy recovery efficiency of 31% for electricity production up to 76% (when heat recovery is included).

The prime advantage of the VPS is the generating of electricity during the process instead of consuming it.

The produced electricity can be utilized by the terminal to reduce purchase from the grid. If there is any surplus production of electricity from the VPS, it can be sold to the grid. In this way real savings can be established that will positively contribute to the sustainable and society responsible enterprising of your company.

The fuel management system will constantly monitor and adjust all settings within the system to ensure an efficient and effective operation. When the system does not detect any vapour it will shut down automatically. The collected vapour is converted into electricity by the gas engine and generator. The recovery of the engine heat can be used for heating storage tanks or/and buildings at the terminal. The VOC emissions are reduced up to 99,9% with an energy recovery efficiency of 31% for electricity production up to 76% (when heat recovery is included).

The prime advantage of the VPS is the generating of electricity during the process instead of consuming it.

The produced electricity can be utilized by the terminal to reduce purchase from the grid. If there is any surplus production of electricity from the VPS, it can be sold to the grid. In this way real savings can be established that will positively contribute to the sustainable and society responsible enterprising of your company.

Meets the world environmental legislation

The VPS meets the worlds most stringent environmental legislation:

- German TA-Luft

- NER (Dutch Emission Guidelines)

- EU Directive 94/63/EC

Economics

The VPS is designed to minimize operational costs. Because the system is fully automatic and remote controlled, no operating personnel is required. The VPS mainly consists of standardized components, such as its engine and generator. Maintenance is done by our mechanics. By far the most significant aspect however is the positive energy balance attained by the process as the VPS generates electricity. A return on excise duty can be granted by the authorities when processing taxed gasoline vapours.

Working on more than 80 different vapours

The VPS is very flexible in its operations. More than 80 different product vapours can be converted into electricity simultaneously, for example benzene, naphta, aceton, MTBE, toluene xylene, gasoline, butene oxide, isopropyl aceton, methanol, etc. can be processed.

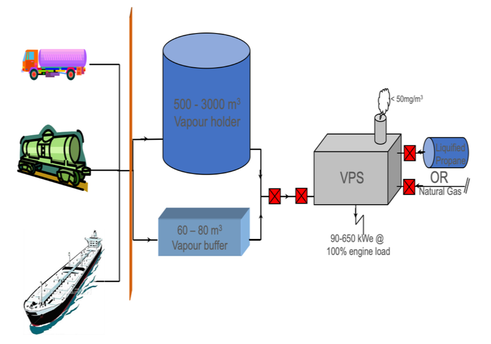

We offer one universal system to tackle many problems. By using different application sizes we can install a solution for every throughput, small or large; at truck, barge or rail tank-filling. The VPS makes you much more independent as an electricity consumer; It can be used as a back-up power unit.

We offer one universal system to tackle many problems. By using different application sizes we can install a solution for every throughput, small or large; at truck, barge or rail tank-filling. The VPS makes you much more independent as an electricity consumer; It can be used as a back-up power unit.