Maximize Efficiency with IPCO Power's FID Reducer: The Premier Sludge Reduction System

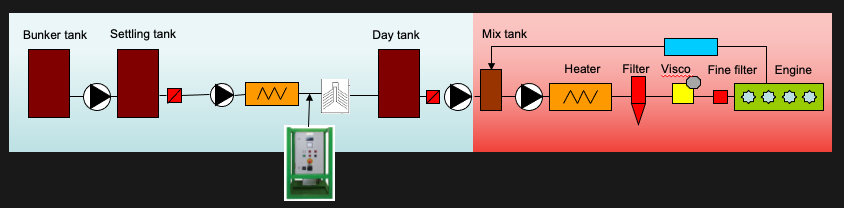

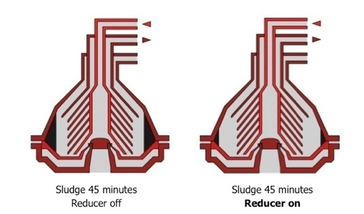

IPCO Power's FID Reducer revolutionizes sludge management by being strategically installed directly before the centrifuge in your fuel processing system. This innovative solution is engineered to significantly decrease fuel droplet size, enabling centrifuges and filters to remove inorganic contaminants more efficiently and maintain cleanliness for extended periods. The result? A dramatic reduction in sludge generation and the extension of centrifuge flushing intervals, streamlining maintenance and enhancing operational efficiency.

Inside Innovation: Explore the FID Reducer’s core features and the technology driving operational efficiency.

Inside Innovation: Explore the FID Reducer’s core features and the technology driving operational efficiency.

Tailored Efficiency for Optimal Performance

The FID Reducer's effectiveness is intricately linked to the size of the asphaltenes in the fuel. With larger asphaltenes particles, our system achieves greater efficiency, converting approximately 10% of asphaltenes into usable fuel. Considering the average asphaltenes content of 6.5% in IF 380 bunker fuel, the potential for fuel recovery and cost savings is substantial.

The FID Reducer's effectiveness is intricately linked to the size of the asphaltenes in the fuel. With larger asphaltenes particles, our system achieves greater efficiency, converting approximately 10% of asphaltenes into usable fuel. Considering the average asphaltenes content of 6.5% in IF 380 bunker fuel, the potential for fuel recovery and cost savings is substantial.

|

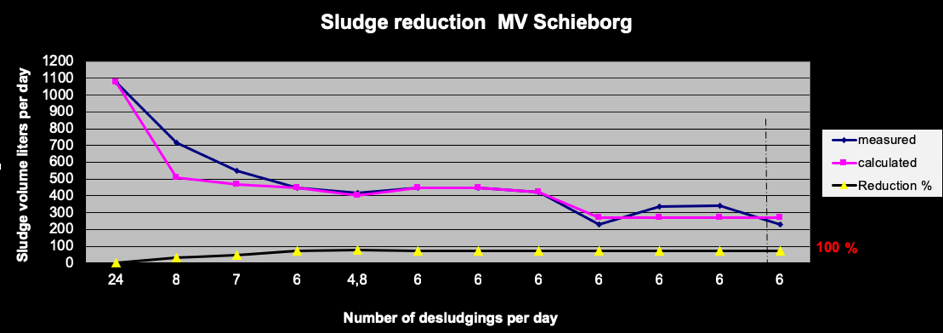

Unparalleled Reduction in Sludge Production

Prepare to witness a remarkable 50 – 80% reduction in sludge production with the FID Reducer. This not only translates to significantly lower disposal costs but also contributes to a more sustainable and environmentally friendly operation. By optimizing the removal of asphaltenes and other contaminants, the FID Reducer ensures your fuel treatment process is both efficient and effective, providing a cleaner fuel output and promoting longer equipment life. |

Invest in Sustainability, Efficiency, and Savings

Embrace the future of fuel treatment with IPCO Power's FID Reducer. By integrating this system into your operations, you're not just enhancing efficiency; you're also investing in the sustainability of your processes and contributing to the global effort to reduce environmental impact. Discover the IPCO difference today and set a new standard in sludge management and fuel optimization.

Embrace the future of fuel treatment with IPCO Power's FID Reducer. By integrating this system into your operations, you're not just enhancing efficiency; you're also investing in the sustainability of your processes and contributing to the global effort to reduce environmental impact. Discover the IPCO difference today and set a new standard in sludge management and fuel optimization.

|

Quick Specifications Overview:

The IPCO Power's FID Reducer is engineered for superior sludge reduction efficiency and sustainability in fuel processing systems. Key highlights include:

|