|

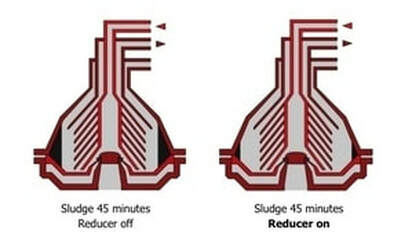

Heavy Fuel Oil (HFO) is not homogenous and has an average droplet size of 70 micron and larger. It contains numerous much larger clusters of asphaltenes and complex long-chain hydro-carbons. It is a refinery waste stream product with a high BTU content used as fuel oil. Centrifuges and automated filters are used to clean the fuel. A percentage of the purchased fuel ends up in the slop tank. HFO needs to be heated and pressurized before it can be used to operated engines or boilers. Exposing fuel to heat and pressure will unavoidably increase the size and mass of the fuel droplet, change the physical condition of the oil and negatively impact the combustion process. Implementing IPCO Power Fluid Shearing Technology reduces fuel droplet size to 3 micron and smaller to enhance the cleaning process and reduce the waste stream going to the slop tank for disposal. IPCO POWER’s FID Reducer Sludge Reduction Systems are installed directly before the centrifuge. As a result of the reduction in fuel droplet size, centrifuges and filters will be able to more effectively remove in-organic contaminants and stay clean much longer. Consequently, sludge generation from centrifuges and filters will be reduced by approx. 50 to 80%(1) as shown in the below diagram. As a result, centrifuge and automated filter flushing intervals will have to be adjusted and will be significantly extended. The volume of sludge discharged from the fuel separator normally consists of three separate constituents. 1. In-organic debris with density higher than water; 2. Organic material (fuel) with a higher density than water and 3. water. The relative ratios depend on the condition and quality of the fuel and on the type/make and adjustment of the fuel separator.

Some separator manufacturers claim that a homogenizer will reduce separator efficiency. They claim that a homogenizer will reduce the of the separator’s ability to remove materials that: 1. have a higher density than water; and 2. reduce the water removal capability. In principle, centrifuges and filters are designed to remove water and in-organic contaminants from the fuel. Allorganic material, meaning “all of the fuel” was purchased to be combusted in the engine and not toget flushed out of centrifuges and filters and into slop tank. The function of the homogenizer is to prevent that on average one percent or more of all the fuel we purchase ends up in the slop tank for disposal. This is accomplished by reducing the size and mass droplet size of the fuel droplets enabling centrifuges and filters to more effectively remove the in-organic debris that happens to be part of the fresh fuel we bunker. Refineries have significantly reduced the amount of cat-fines and other contaminants in today’s HFO.Never the less, engine protection is top priority. And that is exactly where IPCO Power homogenizers make a contribution. They reduce size and mass of the fuel droplet consequently enhancing centrifuge and filter efficiencies. In IPCO Power’s homogenizer, the fuel passes through a 300 micron opening between the homogenizer stator and rotor that spins at 3000 RPM causing the fluid shearing. FRAS Technology(2) has confirmed that a homogenizer has no influence on the number and sizes of the hard (in-organic) particles in the fuel. CIMAC(3) has published a report comparing particle size distribution and particle count with and without the use of a homogenizer before the centrifuge. In its conclusion, CIMAC reports a 4-6% improvement in particle removal efficiency, when using a homogenizer/separator combination instead of ONLY a separator. IPCO Power agrees with the statements made by CIMAC(4) and the Norwegian Marine Technology Research Institute(5). Both institutions claim that when the water content in the fuel exceeds 1%, the homogenizer + separator in tandem will remove less water from the fuel. However, according to ISO 8217:2005 norm for the fuel taken onboard when bunkering has to be less than 0,5%. Consequently, totally emulsifying the trace amounts of water that may still be coming on board when bunkering is an excellent benefit and contributes to engine and injection system protection. Never the less, accidents may happen and the 0.5% water-in-fuel limit may be exceeded. Therefore IPCO Power recommends installing a water in oil sensor/alarm module to automatically shut down the homogenizer in the event of out of spec fuel. Any reduction in separator efficiency will be visible in short notice. IPCO Power is proud to say that ALL the homogenizers it has installed since 2006 operate as expected. And, during these years, all our equipment has met and exceeded customer expectations. 1 Vessel Evaluation Reports (MV Makiri Green, MV Schieborg) 2 FRAS Technology – Oil Analysis 08-21693 3 CIMAC Paper 160 – Actual Capability of Shipboard Fuel Oil Pre-treatment Systems (in cooperation with NYK LINE) 4 CIMAC Paper 160 – Actual Capability of Shipboard Fuel Oil Pre-treatment Systems (in cooperation with NYK LINE) 5 Norwegian Marine Technology Research Institute – Project Green Efforts for Existing Ships |

Categories

All

Archives

March 2024

AuthorBart Sluimer is the General Manager of IPCO Power. IPCO Power is an international company specialized in environmental solutions for the petrochemical-, shipping- and power industry. Find us on google+ and twitter |