Fuel Homogenization: Enhancing Efficiency with IPCO Power

IPCO Power's pioneering fuel homogenizer technology redefines fuel efficiency by reducing fuel droplet size to 3 microns or smaller. This advancement delivers multifaceted benefits, from significant sludge reduction to optimized combustion, tailored to the specific needs of each installation.

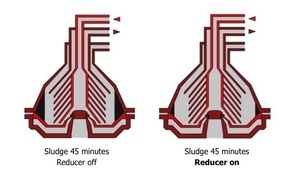

Sludge ReductionOur technology dramatically enhances the efficiency of centrifuges and filters in removing inorganic contaminants, slashing sludge production by 50 to 80%. This not only boosts the yield of usable fuel from your bunker but also extends maintenance intervals for centrifuges and automated filters, enhancing operational efficiency and sustainability.

FID Reducer |

Combustion ImprovementBy ensuring fuel droplets are consistently 3 microns or smaller, our system significantly improves fuel atomization. This enhanced interaction between fuel and oxygen boosts combustion efficiency, yielding fuel savings of 1-1.5% for 4-stroke engines and 2-2.5% for 2-stroke engines, alongside lower emissions.

FID Improver |

Water in fuel emulsionOur solution elevates combustion efficiency and emission control by integrating water into fuel, creating a stable emulsion that enhances atomization. This process leads to more complete combustion, reducing fuel consumption and cutting down on NOx, HC, and PM pollutants. Implemented by leading industry players like Carnival, our FID Injector supports environmental compliance and operational excellence.

FID Injector |

Tank treatmentFuelGuard represents a breakthrough in tank treatment, optimizing the performance and longevity of diesel and biodiesel fuels. Leveraging our homogenization technology, FuelGuard ensures fuel integrity and efficiency, safeguarding engine health and maximizing fuel economy.

FID FuelGuard Tank Treatment System |

Controlled blendingOur system offers precision blending capabilities, allowing for adjustments in sulfur content, viscosity, or the incorporation of biofuels. The FID Blender guarantees a stable and homogenous fuel mix, meeting specific regulatory and performance criteria with reliability.

FID Blender |

CombinationUnlock unparalleled efficiency and environmental benefits with IPCO Power's synergistic approach to fuel treatment. Our tailored combination of the FID Reducer, FID Improver, and the optional FID Injector represents the pinnacle of innovation in emissions control and fuel quality enhancement.

Combination |

|

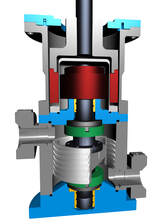

What is a homogenizer

Our product lineup is anchored by rotor-stator homogenizers, versatile across various fuels. These units integrate a high-speed inner rotor and a fixed outer stator in a homogenization chamber, subjecting fuel to intense mechanical forces and cavitation. This process yields a uniform fuel mixture, boosting combustion efficiency for marine and land-based power systems. |

Key Components for Multiple Fuel Types

Our fuel homogenizers are meticulously designed for broad fuel compatibility and operational demands:

Base and Motor: Form the core, providing essential power for homogenization.

Magnetic Coupling: Enables effective rotor motion transfer, enhancing longevity and minimizing maintenance.

Homogenization Chamber: Central to the device, it houses the rotor and stator. Its tailored design ensures versatile fuel processing.

Our fuel homogenizers are meticulously designed for broad fuel compatibility and operational demands:

Base and Motor: Form the core, providing essential power for homogenization.

Magnetic Coupling: Enables effective rotor motion transfer, enhancing longevity and minimizing maintenance.

Homogenization Chamber: Central to the device, it houses the rotor and stator. Its tailored design ensures versatile fuel processing.

IPCO Power: Pioneering Sustainable Fuel Solutions

With IPCO Power's fuel homogenizer technology, you're not just optimizing fuel usage—you're investing in a sustainable future. Our comprehensive solutions ensure your operations are efficient, compliant, and environmentally responsible. Discover the IPCO difference and propel your enterprise towards greener horizons.

With IPCO Power's fuel homogenizer technology, you're not just optimizing fuel usage—you're investing in a sustainable future. Our comprehensive solutions ensure your operations are efficient, compliant, and environmentally responsible. Discover the IPCO difference and propel your enterprise towards greener horizons.