|

Some manufacturers of separators have voiced concerns regarding the influence of homogenizers on the performance of separators. Their worry is that homogenizers could affect the separator’s ability to efficiently separate substances denser than water and impede the process of water extraction. Fundamentally, the purpose of centrifuges and filters is to extract water and inorganic impurities from fuel, with the assumption that organic components of the fuel will be combusted in the engine instead of being discharged into the slop tank. Homogenizers aim to minimize fuel waste to less than one percent by reducing the size and mass of fuel droplets, thereby enhancing the ability of centrifuges and filters to remove inorganic pollutants from new fuel. Refineries have advanced in reducing contaminants like cat-fines in Heavy Fuel Oil (HFO), and protecting engines is a top priority. IPCO Power's homogenizers are crucial in this process by diminishing fuel droplet size and mass, which in turn boosts the performance of centrifuges and filters. In the IPCO Power homogenizer, fuel is forced through a 300-micron gap between the stator and rotor of the homogenizer, which spins at 3000 RPM, creating fluid shearing. The sludge expelled by the fuel separator is typically composed of three main elements:

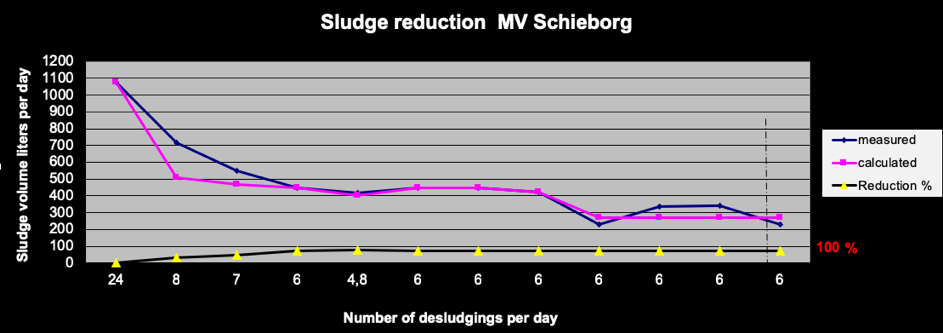

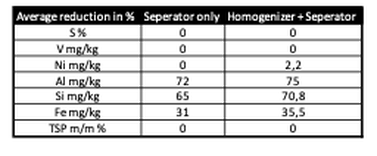

The ratio of these elements can vary based on the fuel’s state, quality, and the specifications and settings of the fuel separator. FRAS Technology has verified that homogenizers do not affect the volume and size of the hard (inorganic) particles in the fuel. A report by CIMAC, comparing particle size distribution and count with and without a homogenizer prior to centrifugation, indicated a 4-6% improvement in particle removal efficiency with the use of a homogenizer/separator system compared to using a separator alone. IPCO Power has conducted thorough research on the efficiency of separators through onboard installations, analyzing bunker samples before and after treatment by the separator, both with and without the homogenizer active. These studies showed that the presence of the homogenizer notably enhanced the separator’s removal effectiveness and achieved a reduction in sludge by 50 to 80%. Any decline in separator efficiency would be quickly noticeable. IPCO Power is pleased to report that since 2006, all installed homogenizers have consistently met and surpassed customer expectations, delivering the high level of performance our customers require. IPCO Power welcomes any inquiries and is ready to provide further details as needed.

Comments are closed.

|

Categories

All

Archives

March 2024

AuthorBart Sluimer is the General Manager of IPCO Power. IPCO Power is an international company specialized in environmental solutions for the petrochemical-, shipping- and power industry. Find us on google+ and twitter |

||||||||||||||||||