|

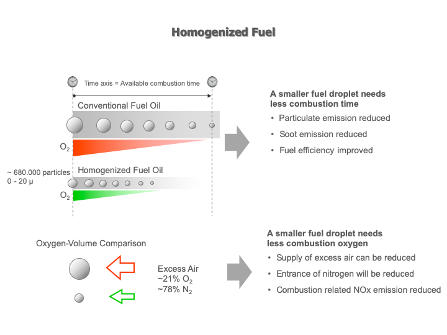

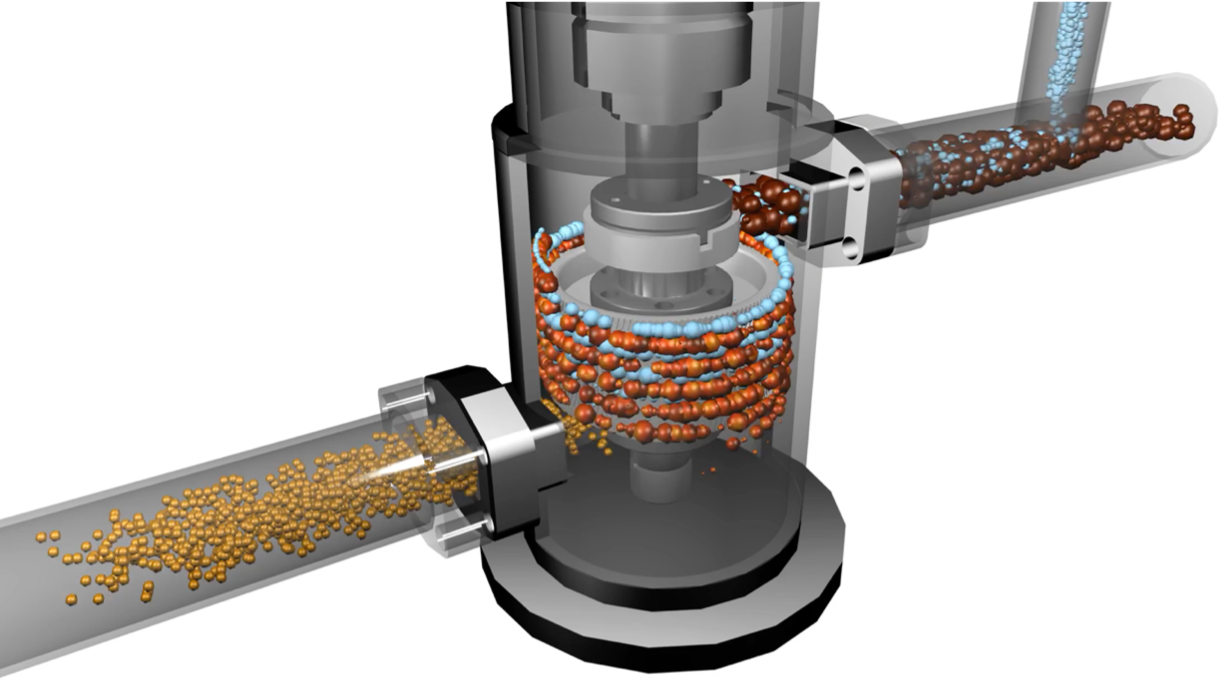

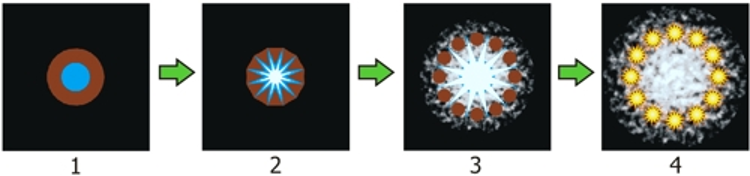

At the moment most vessels are focusing in reducing operational costs. Fuel is the biggest operational costs. The use of the IPCO Power WFE system (FID Injector) will result in more effective combustion, lower fuel consumption and a reduction of NOx, Soot and PM pollutants, while the engine’s combustion chambers, pistons, exhaust system and lube oil will stay much cleaner. Currently 130 Water Fuel Emulsion systems from IPCO are in operation! The benefits are coming from the 2 parts of treatment: Homogenizer: Firstly, the fuel homogenizer reduces fuel droplet size to 3 micron and smaller. Smaller fuel droplets enhance combustion, lower emissions and improve fuel economy. Adding water to the fuel: Secondly the WFE system the FID Injector is a combustion improvement system designed to create a stable “water in fuel” emulsion. The system is installed before the mixing tank. The implementation of emulsified fuel significantly enhances fuel atomization and distribution in the combustion chamber. Schematic representation of combusting fuel emulsion:

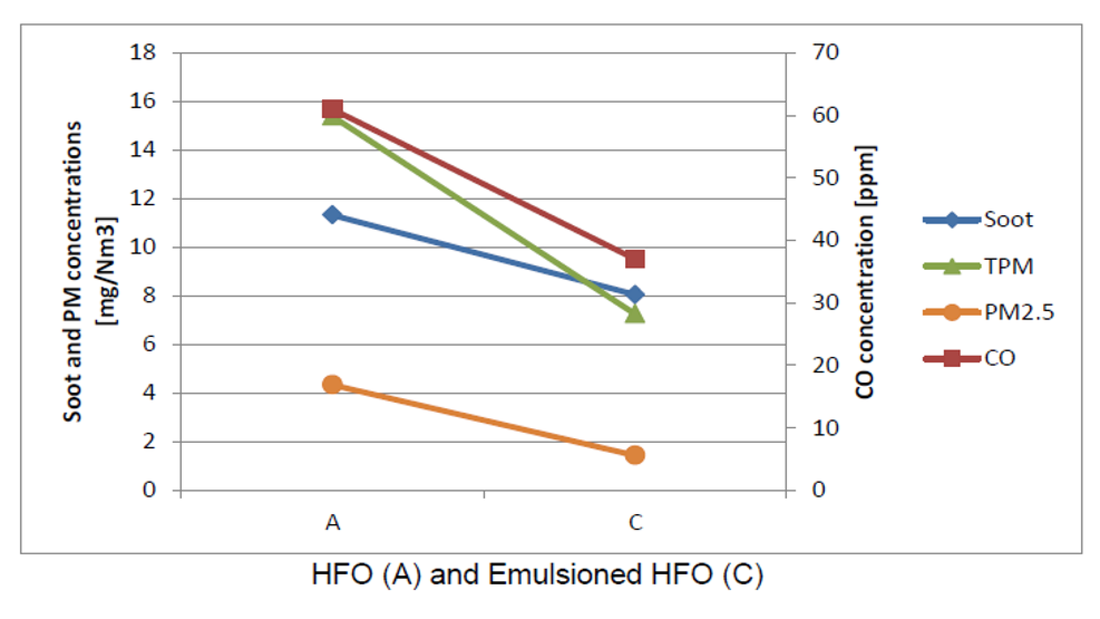

NOx reductions using water in fuel emulsions are significant; approximately 1% NOx reduction is achieved for every 1% injected water. Using existing fuel systems, water content is limited to 20%. The FID Injector has a cost advantage over other systems, primarily due to its simplicity in system installation and operation. With the better combustion your exhaust will stay cleaner. This will lead to cleaner wash water from scrubber systems. The FID Injector (WFE) system is one of the simplest systems to reduce the particulate matter and soot emissions significantly. The system will target these emissions at the source, the fuel. Operational costs are low as the only major requirement to the Injector is the water addition. The FID Injector has a small footprint, and all necessary components are available inside the frame. The FID Injector is installed between booster feed pump and mix tank to simply control the water injection. Benefits from our Water Fuel Emulsions system: Up to 2% fuel saving with a 4 stroke engine and 2,4% with a 2 stroke. Less engine maintenance Up to 20% NOx reduction Less black smoke Up to 90% PM and Soot reduction Assisting your ships scrubber system (keep the scrubber cleaner) Scrubber wash water will be cleaner Example of the benefits: The soot reduction was confirmed for example by the Seabourn Odyssey. After installation of the WFE system they had half of the soot waste during the monthly cleaning of the EGB. Steam pipes before and after the installation of the IPCO WFE system. Evaluation on board HAL RyndamResults during the evaluation on board HAL Ryndam were the same as the evaluation from Lloyds Register with Carnival Corp. Emission reduction measured on board vessel from Costa |

Categories

All

Archives

March 2024

AuthorBart Sluimer is the General Manager of IPCO Power. IPCO Power is an international company specialized in environmental solutions for the petrochemical-, shipping- and power industry. Find us on google+ and twitter |