Revolutionizing Emissions Control: Water Fuel Emulsion (WFE) System by FID Injector

Innovative Emissions Purification and Combustion Enhancement

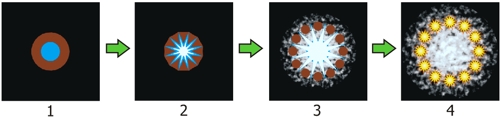

Our Water Fuel Emulsion (WFE) system represents a leap forward in emissions purification technology. Designed to create a stable water-in-fuel emulsion, this system significantly improves the atomization and distribution of fuel within the combustion chamber. The result? More efficient combustion, reduced fuel consumption, and a substantial decrease in NOx, HC, and PM emissions. Furthermore, the WFE system promotes cleaner combustion chambers, pistons, exhaust systems, and lube oil, maintaining the engine's optimal performance.

Our Water Fuel Emulsion (WFE) system represents a leap forward in emissions purification technology. Designed to create a stable water-in-fuel emulsion, this system significantly improves the atomization and distribution of fuel within the combustion chamber. The result? More efficient combustion, reduced fuel consumption, and a substantial decrease in NOx, HC, and PM emissions. Furthermore, the WFE system promotes cleaner combustion chambers, pistons, exhaust systems, and lube oil, maintaining the engine's optimal performance.

|

|

Eco-Friendly Impact with Significant NOx Reduction

Emulsifying water into fuel achieves remarkable reductions in NOx emissions—approximately a 1% decrease for every 1% of water added, with the capability to incorporate up to 20% water using existing fuel systems. This not only enhances environmental sustainability but also offers a cost-effective alternative to traditional emissions reduction methods. |

The FID Injector Advantage: Simplicity and Efficiency

Our FID Injector system outperforms alternatives by combining ease of installation with superior operational efficiency. It ensures cleaner exhaust emissions and contributes to more environmentally friendly wash water from scrubber systems. Designed to target particulate matter and soot emissions directly at the fuel source, the FID Injector provides an impactful solution for emissions management.

Our FID Injector system outperforms alternatives by combining ease of installation with superior operational efficiency. It ensures cleaner exhaust emissions and contributes to more environmentally friendly wash water from scrubber systems. Designed to target particulate matter and soot emissions directly at the fuel source, the FID Injector provides an impactful solution for emissions management.

Water in fuel emulsion will create a better combustion

|

Operational Excellence and Cost Savings

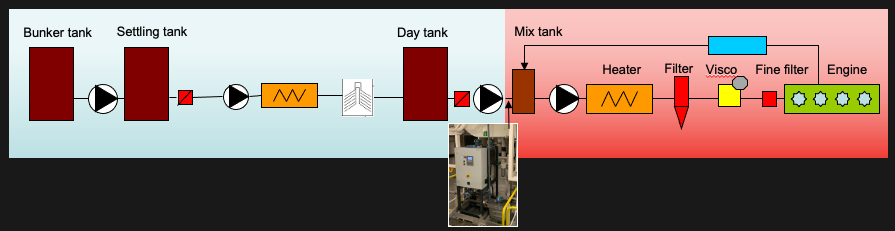

The FID Injector system is characterized by its low operational costs, primarily requiring only the addition of water to the fuel. With a compact design, it integrates seamlessly into existing setups, installed between the booster feed pump and the mix tank for easy control over the water injection process.

The FID Injector system is characterized by its low operational costs, primarily requiring only the addition of water to the fuel. With a compact design, it integrates seamlessly into existing setups, installed between the booster feed pump and the mix tank for easy control over the water injection process.

Unmatched Benefits of the WFE System:

- Fuel Efficiency: Achieve up to 2% fuel savings with 4-stroke engines and 3% with 2-stroke engines.

- Reduced CO2 Emissions: Lower your carbon footprint and contribute to global environmental efforts.

- Enhanced Engine Maintenance: Experience fewer maintenance needs due to cleaner engine components.

- NOx Emissions Reduction: Attain up to a 20% decrease in NOx emissions, supporting compliance with environmental regulations.

- Visibility Improvement: Noticeably reduce black smoke emissions.

- Particulate Matter and Soot Control: Achieve up to 90% reduction, enhancing air quality.

- Scrubber System Support: Assist your ship's scrubber system in maintaining cleanliness, resulting in cleaner scrubber wash water.

- Fuel Efficiency: Achieve up to 2% fuel savings with 4-stroke engines and 3% with 2-stroke engines.

- Reduced CO2 Emissions: Lower your carbon footprint and contribute to global environmental efforts.

- Enhanced Engine Maintenance: Experience fewer maintenance needs due to cleaner engine components.

- NOx Emissions Reduction: Attain up to a 20% decrease in NOx emissions, supporting compliance with environmental regulations.

- Visibility Improvement: Noticeably reduce black smoke emissions.

- Particulate Matter and Soot Control: Achieve up to 90% reduction, enhancing air quality.

- Scrubber System Support: Assist your ship's scrubber system in maintaining cleanliness, resulting in cleaner scrubber wash water.

Embrace Sustainability with FID Injector's WFE System

Adopting the FID Injector's Water Fuel Emulsion system not only elevates your operational efficiency but also reinforces your commitment to environmental stewardship. With significant emissions reductions, fuel savings, and maintenance advantages, it's an investment in a cleaner, more sustainable future. Discover the difference with our WFE system and set a new standard in emissions control and fuel management.

Adopting the FID Injector's Water Fuel Emulsion system not only elevates your operational efficiency but also reinforces your commitment to environmental stewardship. With significant emissions reductions, fuel savings, and maintenance advantages, it's an investment in a cleaner, more sustainable future. Discover the difference with our WFE system and set a new standard in emissions control and fuel management.

|

FID Injector: Quick Specifications Overview

The IPCO Power's FID Injector is a state-of-the-art solution designed for enhancing fuel processing systems. It incorporates a sophisticated Vertical Homogenizer, driven by a magnetic motor coupling, to ensure exceptional operational efficiency and durability. Here are the key specifications: Material & Design: The Vertical Homogenizer at the heart of the FID Injector is crafted from high-strength Aluminum 7075 T6, featuring a special proprietary hard coat for enhanced longevity and resistance to wear. Operational Efficiency: The FID Injector is equipped with a high-pressure water pump and a sophisticated PLC control program, enabling precise and efficient fuel treatment processes. It can handle a maximum pressure of 12 bar, making it suitable for a wide range of fuels including Heavy Fuel Oil (HFO), Marine Diesel Oil (MDO)*, biofuels, and Ultra-Low Sulfur Fuel Oil (ULSFO). Power Compatibility: The system supports a diverse range of power supplies to ensure global compatibility and flexibility in installation. For the main power, it accepts 400V@50Hz or 460V@60Hz, and 690V. Capacity Range: The FID Injector is available in various models to accommodate different capacity needs, ranging from 1,500 liters per hour to 30,000 liters per hour. This scalability ensures that the system can be tailored to meet the specific requirements of your operations. Environmental Impact: Designed with an eye towards sustainability, the FID Injector significantly reduces emissions. This supports eco-friendly operations. The FID Injector embodies IPCO Power's commitment to innovation, efficiency, and environmental stewardship in fuel processing technology. For more detailed information on the FID Injector's full technical specifications, including dimensions, power requirements, and additional features, interested parties are encouraged to contact IPCO Power directly. |