FuelGuard: Revolutionizing Fuel Treatment for Peak Performance

Introduction:

FuelGuard redefines tank treatment technology, offering an innovative solution to enhance diesel and biodiesel fuel performance and longevity. Utilizing state-of-the-art homogenization technology, FuelGuard ensures fuel purity and efficiency, providing exceptional protection for your engines and supporting environmental sustainability.

Core Advantages:

Addressing Biofuel Challenges:

Stability in Biofuels: FuelGuard ensures that biofuels remain homogeneously mixed, combating the tendency for separation and oxidative degradation, thus maintaining fuel quality over time.

Tangible Benefits:

Maximized Fuel Efficiency: Achieve superior combustion and reduced consumption thanks to FuelGuard's consistent fuel blend.

Uninterrupted Performance: Enjoy smooth operations with a reliable fuel supply, free from the common issues of clogged filters and engine disruptions.

Cost Savings: FuelGuard contributes to significant maintenance savings by reducing engine problems and downtime.

Versatile Applications:

FuelGuard is invaluable across numerous sectors, from transportation and agriculture to construction and notably in the marine industry. It's an essential ally for fleets, heavy machinery, and any operation where fuel quality directly impacts performance and efficiency.

Seamless Integration:

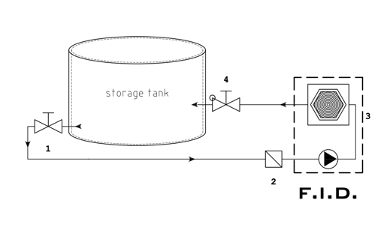

Incorporating FuelGuard into your existing fuel storage system is straightforward. Its automated homogenization process continuously maintains fuel quality, ensuring optimal performance and longevity for your engines.

Embrace Fuel Excellence with FuelGuard

FuelGuard stands as your premier solution for fuel management, combining efficiency, reliability, and environmental responsibility. Elevate your operation's fuel strategy and safeguard your investment with the unparalleled protection of FuelGuard.

FuelGuard redefines tank treatment technology, offering an innovative solution to enhance diesel and biodiesel fuel performance and longevity. Utilizing state-of-the-art homogenization technology, FuelGuard ensures fuel purity and efficiency, providing exceptional protection for your engines and supporting environmental sustainability.

Core Advantages:

- Homogenization Excellence: FuelGuard's cutting-edge technology meticulously blends fuel components, preventing stratification and reducing droplet size to 3 microns. This precision crafting results in a consistently uniform fuel mixture, optimizing combustion and fuel efficiency.

- Extended Engine Life: By preserving fuel quality, FuelGuard minimizes engine wear and tear, significantly lowering maintenance costs and extending the life of your machinery.

- Environmental Integrity: Engineered for eco-friendly performance, FuelGuard facilitates cleaner combustion, leading to reduced emissions and a lesser environmental impact.

- Flexible Capacity: Catering to a broad spectrum of needs, FuelGuard operates effectively for capacities ranging from 200 liters to 30,000 liters per hour, making it suitable for various scales of operation.

Addressing Biofuel Challenges:

Stability in Biofuels: FuelGuard ensures that biofuels remain homogeneously mixed, combating the tendency for separation and oxidative degradation, thus maintaining fuel quality over time.

- Protection Against Contaminants: By preventing microbial contamination, FuelGuard safeguards your fuel against bacteria and fungi, ensuring a clean and efficient fuel system.

Tangible Benefits:

Maximized Fuel Efficiency: Achieve superior combustion and reduced consumption thanks to FuelGuard's consistent fuel blend.

Uninterrupted Performance: Enjoy smooth operations with a reliable fuel supply, free from the common issues of clogged filters and engine disruptions.

Cost Savings: FuelGuard contributes to significant maintenance savings by reducing engine problems and downtime.

Versatile Applications:

FuelGuard is invaluable across numerous sectors, from transportation and agriculture to construction and notably in the marine industry. It's an essential ally for fleets, heavy machinery, and any operation where fuel quality directly impacts performance and efficiency.

Seamless Integration:

Incorporating FuelGuard into your existing fuel storage system is straightforward. Its automated homogenization process continuously maintains fuel quality, ensuring optimal performance and longevity for your engines.

Embrace Fuel Excellence with FuelGuard

FuelGuard stands as your premier solution for fuel management, combining efficiency, reliability, and environmental responsibility. Elevate your operation's fuel strategy and safeguard your investment with the unparalleled protection of FuelGuard.

|

FuelGuard: Quick Specifications Overview

The FuelGuard system stands as a premier solution in the realm of fuel purification and management, engineered to significantly boost the efficiency, reliability, and environmental sustainability of fuel processing and storage activities. This quick overview delves into the essential specifications and features that set FuelGuard apart: Material & Design: Central to FuelGuard's design is a Vertical Homogenizer constructed from robust Aluminum 7075 T6, renowned for its high strength. This component is treated with a special proprietary hard coat, extending its durability and wear resistance, a testament to the system's overall build quality and longevity. Operational Efficiency: At the core of FuelGuard's operational prowess is a dedicated fuel pump paired with an advanced control program, ensuring precise and effective fuel treatment processes. With the capacity to manage a maximum pressure of 12 bar, FuelGuard is adept at processing a broad spectrum of fuels, including Heavy Fuel Oil (HFO), Marine Diesel Oil (MDO), biofuels, and Ultra-Low Sulfur Fuel Oil (ULSFO), showcasing its versatility. Power Compatibility: FuelGuard is designed for global application, accommodating a wide array of power supply standards to guarantee seamless integration anywhere in the world. It is compatible with main power sources of 400V@50Hz or 460V@60Hz, and it also supports 690V, highlighting its adaptability to diverse electrical infrastructures. Capacity Range: Tailored to meet varying operational demands, FuelGuard is offered in several models with capacities ranging from 1,500 liters per hour up to 30,000 liters per hour. This scalability ensures that FuelGuard can be precisely configured to align with specific user requirements, emphasizing its flexibility. Environmental Impact: With a design philosophy centered around sustainability, FuelGuard is capable of operating on any type of fuel, minimizing environmental impact. This capability underscores IPCO Power's dedication to eco-friendly innovations and the reduction of carbon footprints across fuel processing technologies. FuelGuard is a clear representation of IPCO Power's commitment to pushing the boundaries of innovation, efficiency, and environmental stewardship within the fuel processing industry. For those interested in a deeper exploration of FuelGuard's comprehensive technical specifications, including detailed dimensions, power requirements, and additional features, IPCO Power invites direct inquiries to provide tailored information and support. |