|

Homogenizers enhance the fuel's properties, impacting its viscosity index 🔄. A fuel homogenizer will change the surface tension of the fuel. The primary function of a homogenizer is to break down the larger fuel particles into smaller, more uniform sizes, and this process also affects the fuel's surface properties.

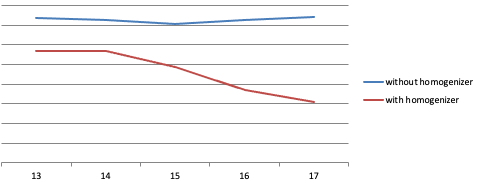

When the fuel is passed through a homogenizer, the high-pressure and shear forces disrupt the larger fuel aggregates, leading to a more homogeneous fuel mixture. This mechanical process reduces the surface tension of the fuel. Lower surface tension improves the fuel's ability to form finer droplets during the atomization process in the engine's fuel injectors, leading to more efficient combustion. By altering the surface tension, the homogenizer helps create a fuel that is more easily vaporized and mixed with air, enhancing the combustion process, improving fuel efficiency, and potentially reducing emissions. For engines with a viscosity range of 14 to 16 cSt, operating at the higher end (16 cSt) when using a homogenizer brings significant benefits: Lower SFOC: Improved fuel atomization boosts combustion efficiency, reducing fuel consumption 💧🔥. Integrating a homogenizer can thus lead to substantial operational savings and environmental benefits. Opt for the higher end of your fuel's viscosity range to see the best results. Learn more at: https://lnkd.in/ewErxvNh Embrace efficiency and sustainability today! 🌱 #FuelEfficiency 💡 #SustainableTechnology ♻️ #MarineEngineering ⚓ #IndustrialEngineering 🏭 At IPCO Power, we've dedicated years to mastering water-fuel emulsion technology. Our journey started with a clear objective: to improve fuel efficiency while reducing emissions in maritime operations. 🌱🚢

Understanding the critical importance of emulsion quality, we've identified the optimal point of water injection - directly at the fuel feed towards the mix tank. This process, devoid of unnecessary circulation, ensures a perfect blend. 🎯💧 Following this, our unique fuel homogenizer takes over, creating a stable, efficient emulsion. This step is crucial: without it, vessels risk the presence of free water in their engines, leading to inefficiencies and potential safety hazards. 🛠️⚙️ Over the years, we've seen various methods and technologies emerge. However, the effectiveness of water-fuel emulsion depends on precise execution and the right equipment. At IPCO Power, we've refined our approach based on comprehensive research and real-world applications. 📊🔍 With more than 140 systems operational worldwide, our technology is not just proven; it's a testament to our commitment to sustainability and efficiency in the maritime industry. 🌍🚀 Our FID Injector system, available since 2008, remains the most cost-effective solution for reducing NOx, CO2, PM, and soot emissions in maritime operations. It's not just about innovation; it's about providing a practical, efficient solution that stands the test of time. 💡💸 Join us in our journey toward cleaner, more efficient maritime operations. IPCO Power is here to guide you every step of the way. 🚢🌿 Learn more at: https://lnkd.in/eZZ9-NV #IPCO Power #MarineInnovation #Sustainability #Efficiency |

Categories

All

Archives

March 2024

AuthorBart Sluimer is the General Manager of IPCO Power. IPCO Power is an international company specialized in environmental solutions for the petrochemical-, shipping- and power industry. Find us on google+ and twitter |